Sulfate Reducing Bacteria (SRB) are a group of microorganisms that play a significant role in various industrial and environmental processes. These bacteria are known for their ability to reduce sulfate to hydrogen sulfide, a process that can lead to corrosion, odor issues, and environmental contamination. The SRB test is a crucial diagnostic tool used to detect and quantify these bacteria in various samples, including water, soil, and industrial fluids. In this blog, we will delve into the importance of the SRB test, its applications, methodologies, and how it can benefit industries and environmental monitoring efforts.

Table of Contents

Understanding Sulfate Reducing Bacteria (SRB)

Sulfate Reducing Bacteria (SRB) are anaerobic microorganisms that thrive in environments devoid of oxygen. They utilize sulfate as an electron acceptor in their metabolic processes, converting it into hydrogen sulfide (H₂S). This metabolic activity can have both beneficial and detrimental effects, depending on the context.

In natural environments, SRB contribute to the sulfur cycle, playing a role in the decomposition of organic matter. However, in industrial settings, their presence can lead to microbiologically influenced corrosion (MIC), which can cause significant damage to pipelines, storage tanks, and other infrastructure. Additionally, the production of hydrogen sulfide can result in foul odors and pose health risks to workers.

What are Sulfate Reducing Bacteria (SRB)?

SRBs are a group of anaerobic microorganisms—meaning they survive without oxygen. Instead of oxygen, they use sulfate compounds to obtain energy. While naturally found in soils, sediments, and waterlogged environments, they become a threat when they enter:

- Oilfield reinjection water

- Industrial cooling systems

- Medical water supplies

- Municipal drinking water pipelines

The most notorious species include Desulfovibrio and Desulfotomaculum. Both are known to generate hydrogen sulfide gas, which smells like rotten eggs and speeds up metal corrosion.

Why is SRB Testing Important in Different Industries?

The impact of SRB goes far beyond just a smelly nuisance. Let’s break it down industry by industry.

Oil & Gas Industry

- SRB cause microbially induced corrosion (MIC) in pipelines.

- Corrosion leads to oil leaks, safety hazards, and billions in losses annually.

- Testing with solutions like the SRB Sulfate Reducing Bacteria Bottle helps operators keep pipelines safe.

Water Treatment & Drinking Water Systems

- SRBs contaminate storage tanks and distribution pipelines.

- They affect water taste, smell, and safety.

- Regular testing using the Sulfate Reducing Bacteria Test Tube ensures clean drinking water.

Medical & Laboratory Settings

- Hospitals and labs require sterile water systems.

- SRBs can interfere with research and contaminate samples.

- Using Microbial Test Tubes for Reinjection Water provides reliable monitoring.

Industrial Equipment & Cooling Systems

- SRBs form biofilms inside equipment.

- Biofilms reduce efficiency and increase maintenance costs.

- Early detection prevents downtime and costly repairs.

The Importance of the SRB Test

The SRB test is essential for several reasons:

- Corrosion Prevention: SRB are a major cause of MIC, which can lead to costly repairs and downtime in industries such as oil and gas, water treatment, and manufacturing. By detecting and monitoring SRB levels, companies can implement preventive measures to mitigate corrosion risks.

- Environmental Monitoring: SRB can contaminate water sources and soil, leading to environmental degradation. Regular testing helps in assessing the impact of SRB on ecosystems and ensuring compliance with environmental regulations.

- Health and Safety: Hydrogen sulfide produced by SRB is toxic and can pose serious health risks to humans and animals. Monitoring SRB levels helps in identifying potential hazards and implementing safety measures.

- Process Optimization: In some industrial processes, such as wastewater treatment, SRB can be beneficial. Understanding SRB activity can help in optimizing these processes for better efficiency.

Methods of SRB Testing

There are several methods available for detecting and quantifying SRB. Each method has its advantages and limitations, and the choice of method depends on the specific application and requirements.

Culture-Based Methods

Culture-based methods involve growing SRB in a laboratory setting using specific growth media. These methods are widely used due to their simplicity and cost-effectiveness.

- Most Probable Number (MPN) Method: This method involves inoculating a series of tubes with a sample and observing for the presence of SRB based on the production of hydrogen sulfide. The MPN method provides a quantitative estimate of SRB concentration.

- Agar Plate Method: In this method, samples are spread on agar plates containing a selective medium for SRB. After incubation, colonies of SRB are counted to determine their concentration.

Molecular Methods

Molecular methods are based on the detection of specific genetic markers associated with SRB. These methods offer higher sensitivity and specificity compared to culture-based methods.

- Polymerase Chain Reaction (PCR): PCR is a widely used molecular technique that amplifies specific DNA sequences of SRB. This method allows for the detection of SRB even at low concentrations.

- Fluorescence In Situ Hybridization (FISH): FISH involves using fluorescently labeled probes that bind to specific RNA sequences in SRB cells. This method allows for the visualization and quantification of SRB in environmental samples.

Electrochemical Methods

Electrochemical methods measure the activity of SRB based on their metabolic products, such as hydrogen sulfide.

- Electrochemical Sensors: These sensors detect the presence of hydrogen sulfide produced by SRB. They offer real-time monitoring and are suitable for continuous monitoring in industrial settings.

Microscopic Methods

Microscopic methods involve the direct observation of SRB cells using microscopy.

- Phase-Contrast Microscopy: This technique allows for the visualization of SRB cells in environmental samples. It is often used in combination with staining techniques to enhance visibility.

Choosing the Right SRB Test Kit

When selecting an SRB test kit, it is essential to consider several factors to ensure that the kit meets your specific needs.

- Sensitivity: The sensitivity of the test kit determines its ability to detect low concentrations of SRB. Choose a kit with high sensitivity if you need to detect SRB at low levels.

- Specificity: The specificity of the test kit determines its ability to distinguish SRB from other microorganisms. Choose a kit with high specificity to avoid false-positive results.

- Ease of Use: Consider the ease of use of the test kit, especially if it will be used in the field or by non-specialists.

- Cost: Consider the cost of the test kit, including any additional reagents or equipment required.

- Turnaround Time: Consider the turnaround time for results, especially if timely decision-making is critical.

- Portability: If the test kit will be used in the field, consider its portability and ease of transport.

SRB Testing Products from Siny Medical

At Siny Medical, we offer a range of SRB testing products designed to meet the needs of various industries and applications. Our products are designed to provide accurate and reliable results, ensuring confidence in the data obtained.

SRB Sulfate Reducing Bacteria Bottle

Our SRB Sulfate Reducing Bacteria Bottle is designed for the detection and quantification of SRB in various samples. The bottle contains a selective growth medium that promotes the growth of SRB while inhibiting other microorganisms. The bottle is easy to use and provides rapid results, making it ideal for field testing.

Sulfate Reducing Bacteria Test Tube

Our Sulfate Reducing Bacteria Test Tube is another excellent option for SRB testing. The test tube contains a selective medium that allows for the growth of SRB, and the results can be easily interpreted based on the production of hydrogen sulfide. The test tube is cost-effective and suitable for use in both laboratory and field settings.

Microbial Test Tube for Reinjection Water

Our Microbial Test Tube for Reinjection Water is specifically designed for the detection of microorganisms, including SRB, in reinjection water used in the oil and gas industry. The test tube contains a selective medium that promotes the growth of SRB, and the results can be easily interpreted based on the production of hydrogen sulfide. The test tube is cost-effective and suitable for use in both laboratory and field settings.

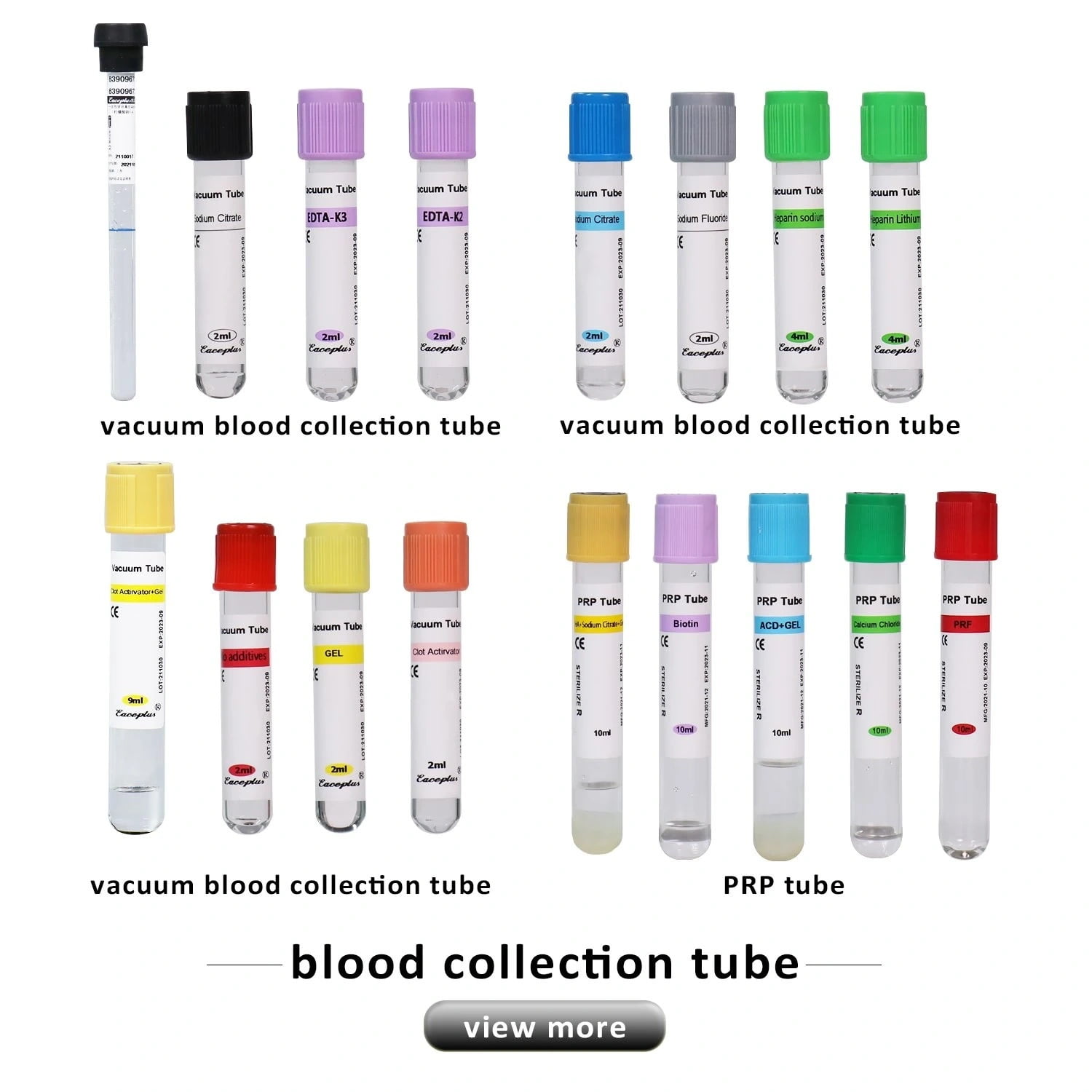

Products Available for SRB Testing from Siny Medical

Siny Medical provides international standard SRB testing products, trusted across industries. Some key solutions include:

- Bacterial Test Tubes – multiple options for labs and industries.

- SRB Test Bottles – ideal for oilfield use.

- Sulfate Reducing Bacteria Test Tubes – standard detection method.

- Microbial Test Tubes for Reinjection Water – tailored for water injection systems.

👉 Learn more or request a quote through Siny Medical’s Contact Page.

Also check their YouTube channel for demos and the Made-in-China profile for business information.

Conclusion

The SRB test is a crucial diagnostic tool for detecting and quantifying sulfate-reducing bacteria in various samples. The test has a wide range of applications, from corrosion prevention in the oil and gas industry to environmental monitoring and water treatment. By using SRB test kits, industries and environmental monitoring efforts can benefit from ease of use, cost-effectiveness, rapid results, and accuracy.

At Siny Medical, we are committed to providing high-quality SRB testing products that meet the needs of our customers. Whether you are looking for a simple and cost-effective test tube or a more advanced testing solution, we have the products you need to ensure accurate and reliable results.

With advanced products like the SRB Test Tubes and Microbial Test Tubes from Siny Medical, testing has never been easier or more reliable.

FAQs

What does an SRB test detect?

It detects the presence of sulfate reducing bacteria that cause corrosion and contamination.

How long does an SRB test take?

Typically 3–7 days with culture methods, while rapid tests can show results in a few hours.

Why is SRB dangerous for oil pipelines?

Because SRB produce hydrogen sulfide gas, which corrodes pipelines and causes leaks.

Can SRB affect drinking water?

Yes, they can change taste, odor, and safety of drinking water supplies.

Where can I buy reliable SRB test kits?

From trusted suppliers like Siny Medical, which offers a full range of SRB test tubes and bottles.