In the healthcare industry, finding reliable surgical consumables manufacturers is crucial for ensuring patient safety and optimal surgical outcomes. This comprehensive guide aims to equip healthcare professionals and businesses with the knowledge necessary to select trustworthy suppliers.

From understanding the importance of quality and compliance to evaluating manufacturing capabilities and customer service, we will explore the key factors that contribute to a successful partnership with surgical consumables manufacturers.

A variety of equipment is provided by medical equipment suppliers to engineering companies, labs, manufacturers, or healthcare facilities hospital consumables manufacturers.

Depending on the business, they provide orthopedic and prosthetic equipment as well as surgical, medicinal, and hospital instruments. They also provide tools and equipment for the dentistry industry. Most businesses also sell lesser quantities of personal care products including cosmetics and medications.

Table of Contents

- 1 What are surgical consumables?

- 2 Reliable Surgical Consumables Manufacturers

- 2.1 Benefits of surgical consumables

- 2.2 1. Introduction

- 2.3 2. The Significance of Surgical Consumables

- 2.4 Enhancing Surgical Precision

- 2.5 3. Understanding Surgical Consumables Manufacturers

- 2.6 Research and Development:

- 2.7 4. Customer Support and After-Sales Service

- 2.8 5. Supply Chain and Distribution Network

- 2.9 Conclusion

- 3 FAQs (Frequently Asked Questions)

- 3.0.1 Q1: How do surgical consumables manufacturers ensure the quality of their products?

- 3.0.2 Q2: Can surgical consumables manufacturers customize their products according to specific requirements?

- 3.0.3 Q3: What are some emerging technologies in surgical consumables manufacturing?

- 3.0.4 Q4: How do surgical consumables manufacturers contribute to sustainability?

- 3.0.5 Q5: How important is the supply chain and distribution network of surgical consumables manufacturers?

What are surgical consumables?

Having the right surgical supplies is crucial to a successful procedure. Gloves, scrubs, gowns, gauze, bandages, masks, and drapes are examples of surgical consumables. They may aid in reducing the risk of surgical infection for both the patient and the surgeons. All surgical supplies are disposable and should only be used once before being discarded.

Reliable Surgical Consumables Manufacturers

Benefits of surgical consumables

Any surgical procedure requires the use of surgical consumables. They can increase a surgical procedure’s effectiveness and accuracy and help to avert potential problems. The following are some justifications for thinking about purchasing surgical supplies:

One advantage of surgical supplies is that they help reduce the danger of infection. Utilizing surgical supplies can lessen the possibility of cross-contamination during surgery, enhancing patient and surgical team safety.

The effectiveness and precision of a surgical process can be increased with the use of surgical consumables. Surgical consumables can assist save the time needed for surgery and lessen the likelihood of problems by supplying the proper instruments and equipment.

Surgical supplies can aid in avoiding potential issues. Disposable medical supplies manufacturers can help to avoid potentially risky situations during surgery by offering the proper tools and equipment.

1. Introduction

In the fast-paced world of healthcare, the availability of high-quality surgical consumables is crucial for patient safety and positive treatment outcomes. Surgical consumables manufacturers are responsible for producing and delivering these essential supplies to healthcare facilities worldwide. The role of these manufacturers provides insights into the factors to consider when choosing a reliable supplier.

2. The Significance of Surgical Consumables

Surgical consumables encompass a wide range of products that are used during surgical procedures. These include gloves, masks, drapes, gowns, syringes, needles, sutures, and more. The significance of these consumables lies in their ability to maintain sterility, prevent cross-contamination, and minimize the risk of infections during surgeries. They create a barrier between the surgical team and the patient, ensuring a safe and controlled environment for the procedure.

Surgical consumables play a crucial role in the field of healthcare, particularly during surgical procedures. These essential supplies are of significant importance for several reasons:

- Maintaining Sterility: Surgical consumables, such as gloves, masks, and drapes, create a sterile environment in the operating room. They act as a barrier between the surgical team and the patient, preventing the transmission of microorganisms and reducing the risk of surgical site infections.

- Preventing Cross-Contamination: By using disposable surgical consumables, healthcare professionals minimize the chances of cross-contamination between patients. Single-use items, such as syringes and needles, eliminate the risk of transmitting bloodborne pathogens and other infectious agents.

- Infection Control: Surgical consumables, including sterilization wraps and adhesive tapes, contribute to infection control measures. These supplies help secure and protect surgical instruments, ensuring that they remain sterile until they are used during the procedure.

- Safety for Healthcare Workers: Surgical consumables not only protect patients but also safeguard healthcare workers. Personal protective equipment (PPE), such as gloves, masks, and gowns, shields medical staff from potential exposure to harmful substances, bodily fluids, and hazardous materials.

Enhancing Surgical Precision

Specific surgical consumables, like sutures and surgical meshes, assist in wound closure and tissue repair. These supplies enable surgeons to achieve precise and secure wound closure, promoting optimal healing and reducing the risk of complications.

- Efficient Surgical Workflow: Having readily available surgical consumables streamlines the surgical workflow. Laboratory equipment surgeons and operating room staff can focus on the procedure without interruptions, ensuring smooth and efficient surgical interventions.

- Standardization and Quality Assurance: Surgical consumables are produced under strict quality control standards and regulations. Their standardized manufacturing processes and materials ensure consistent quality, providing healthcare professionals with reliable products for patient care.

- Compliance with Regulatory Requirements: Healthcare facilities must comply with regulatory guidelines and standards related to surgical procedures. The use of appropriate surgical consumables ensures adherence to these regulations, maintaining the highest level of patient safety and care.

- Patient Confidence and Trust: When patients observe healthcare providers using sterile surgical consumables, it instills confidence and trust in the quality of care they receive. Patients feel assured that their well-being is prioritized, fostering a positive patient experience.

- Global Healthcare Standards: The significance of surgical consumables extends beyond individual healthcare facilities. These supplies are essential components of global healthcare standards, ensuring consistent infection control practices and quality care worldwide.

3. Understanding Surgical Consumables Manufacturers

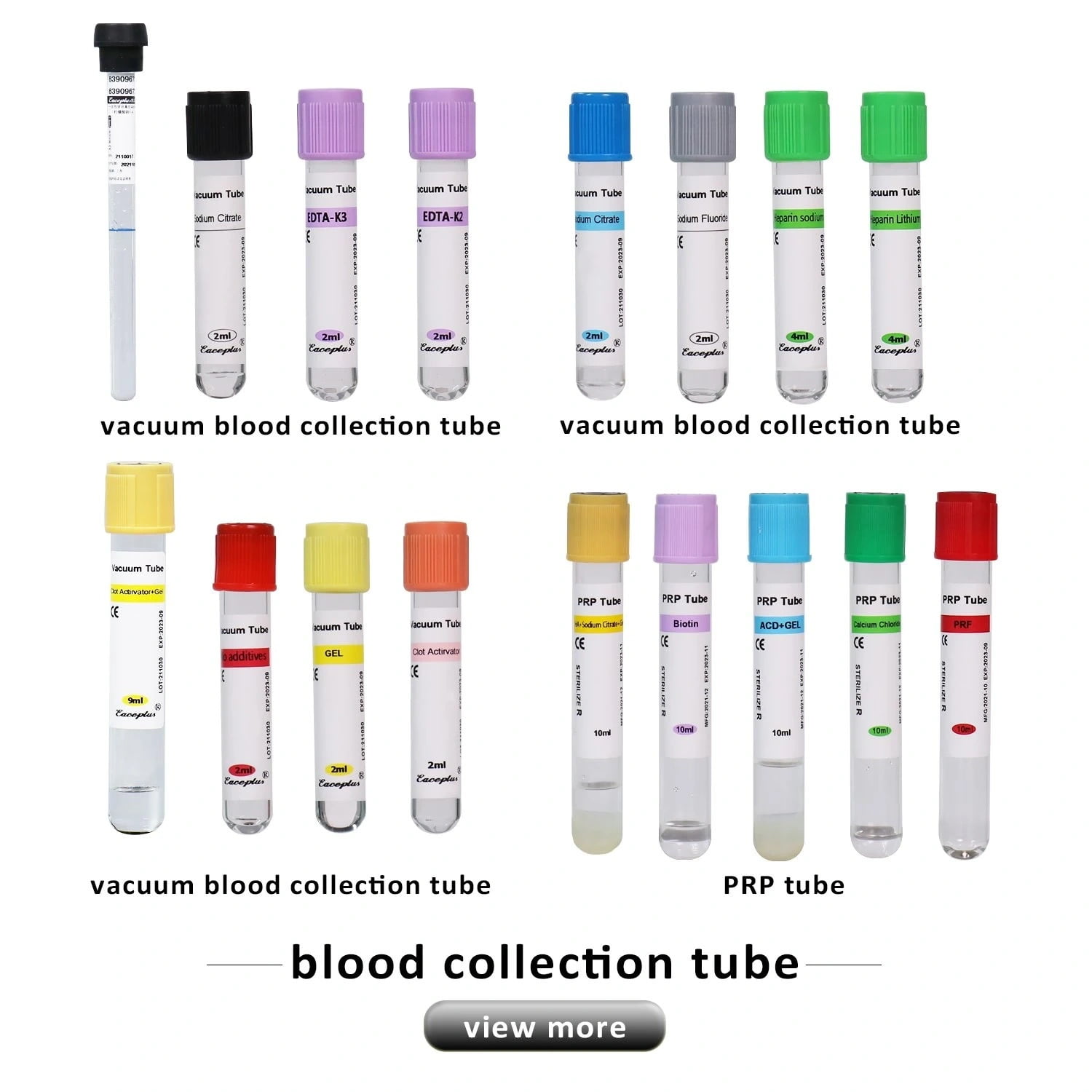

Surgical consumables manufacturers are specialized companies dedicated to the production of medical supplies used in blood collection tubes. They operate under strict quality control measures and adhere to international standards and regulations. These manufacturers utilize advanced manufacturing processes and technologies to ensure the highest level of quality and consistency in their products.

- Expertise in Surgical Supplies: Surgical consumables manufacturers possess in-depth knowledge and expertise in producing a wide range of products that are essential for surgical procedures. They understand the unique requirements of different surgeries and strive to meet the specific needs of healthcare providers.

- Quality Assurance: These manufacturers follow strict quality assurance protocols to ensure that their products meet the highest standards. They adhere to international regulations and certifications to demonstrate their commitment to delivering safe and reliable surgical consumables.

- Advanced Manufacturing Processes: Surgical consumables manufacturers employ advanced manufacturing processes to ensure precision and consistency in their products. They leverage technology and automation to optimize production efficiency and minimize the risk of defects.

- Product Customization: Leading manufacturers offer customization options to accommodate the diverse needs of healthcare facilities. They work closely with their clients to understand their specific requirements and provide tailored solutions that align with their preferences.

- Comprehensive Product Range: A reputable surgical consumables manufacturer offers a comprehensive range of products to meet the varied needs of surgical procedures. This includes gloves, masks, gowns, drapes, syringes, needles, sutures, and other essential items. Having a diverse product portfolio allows healthcare providers to source all their required supplies from a single trusted manufacturer.

- Quality Certifications: Manufacturers that prioritize quality often hold certifications such as ISO 13485. These certifications validate their adherence to stringent quality management systems and affirm their commitment to continuous improvement and customer satisfaction.

Research and Development:

- Surgical consumables manufacturers invest in research and development to stay at the forefront of medical advancements. They strive to innovate and introduce new products or improve existing ones to enhance patient safety, comfort, and overall surgical outcomes.

- Regulatory Compliance: Compliance with regulatory guidelines and standards is of utmost importance to surgical consumables manufacturers. They stay up-to-date with the latest regulations and ensure that their products meet all necessary compliance requirements, ensuring patient safety and legal adherence.

- Global Distribution Network: To ensure the timely delivery and availability of their products, surgical consumables manufacturers maintain a robust global distribution network. This enables them to efficiently serve healthcare facilities worldwide and contribute to the seamless flow of medical supplies.

4. Customer Support and After-Sales Service

Superior customer support and after-sales service are indicators of a reputable surgical consumables manufacturer. They should have a dedicated customer support team that is responsive and knowledgeable, ready to address any queries or concerns. Additionally, they should offer efficient after-sales service, including assistance with product usage, troubleshooting, and warranty support.

5. Supply Chain and Distribution Network

Efficient supply chain management and a robust distribution network are crucial aspects to consider when choosing a surgical consumables manufacturer. A well-established manufacturer should have streamlined processes in place to ensure the timely delivery and availability of their products. They should have strategic partnerships with reliable logistics providers to ensure seamless distribution to healthcare facilities worldwide.

You can find the related products in Surgical Sutures, we are a professional manufacturer of Surgical Sutures. We focused on international export product development, production, and sales. We have improved the quality control processes of Surgical Sutures to ensure each export-qualified product.

If you want to know more about the products in Surgical Sutures, please click the product details to view parameters, models, pictures, prices, and other information about Surgical Sutures.

Whether you are a group or an individual, we will do our best to provide you with an accurate and comprehensive message about Surgical Sutures!

Conclusion

Surgical consumables manufacturers play a vital role in ensuring the availability of high-quality medical supplies for surgical procedures. When selecting a manufacturer, factors such as quality assurance, product range, manufacturing processes, pricing, supply chain efficiency, and customer support should be carefully evaluated. By choosing a reliable and reputable manufacturer, healthcare providers can enhance patient safety, improve surgical outcomes, and contribute to the overall efficiency of healthcare delivery.

FAQs (Frequently Asked Questions)

Q1: How do surgical consumables manufacturers ensure the quality of their products?

A1: Surgical consumables manufacturers adhere to strict quality assurance protocols and often hold certifications such as ISO 13485. They implement rigorous testing, inspections, and quality control measures to ensure the highest standards for their products.

Q2: Can surgical consumables manufacturers customize their products according to specific requirements?

A2: Yes, reputable manufacturers offer customization options to meet specific needs and preferences. They work closely with healthcare providers to understand their requirements and provide tailored solutions.

Q3: What are some emerging technologies in surgical consumables manufacturing?

A3: Emerging technologies in surgical consumables manufacturing include the integration of smart sensors for real-time monitoring, the use of nanomaterials for enhanced performance, and the implementation of automation for improved efficiency.

Q4: How do surgical consumables manufacturers contribute to sustainability?

A4: Leading manufacturers are adopting sustainable practices, such as reducing waste generation, utilizing eco-friendly materials, and implementing energy-efficient manufacturing processes. They strive to minimize their environmental impact and promote sustainable healthcare practices.

Q5: How important is the supply chain and distribution network of surgical consumables manufacturers?

A5: An efficient supply chain and distribution network ensure timely delivery and availability of surgical consumables. This is crucial for healthcare facilities to have uninterrupted access to the necessary supplies, ultimately benefiting patient care.